No products in the cart.

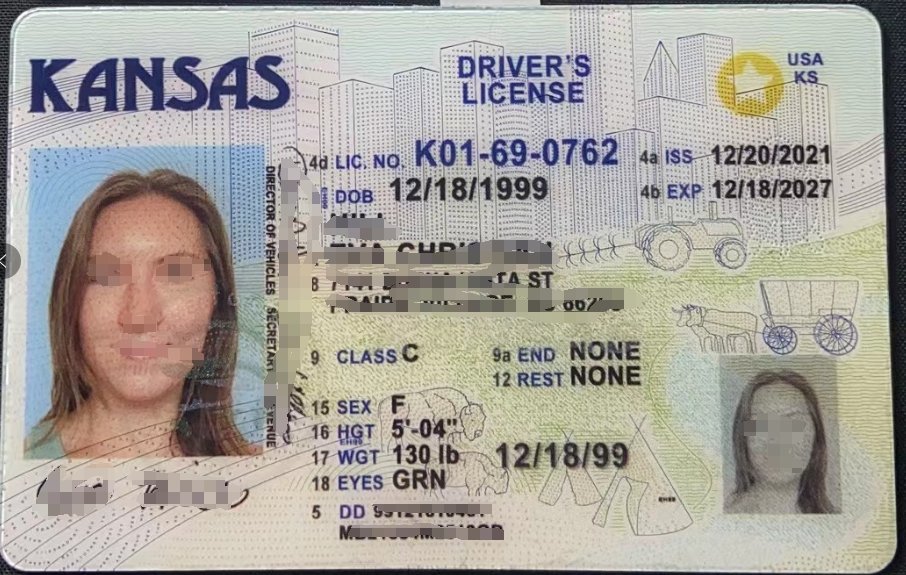

Return To ShopKS Kansas

$120.00 Original price was: $120.00.$100.00Current price is: $100.00.

Get 2-3IDs 35% 0FF

Get 4-9IDs 45% 0FF

Get 4-9IDs 45% 0FF

Get 4-9IDs 45% 0FF

1. What are the processes?

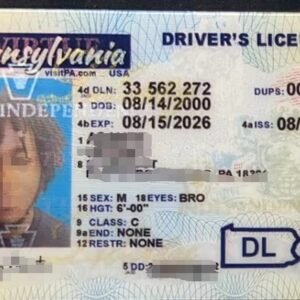

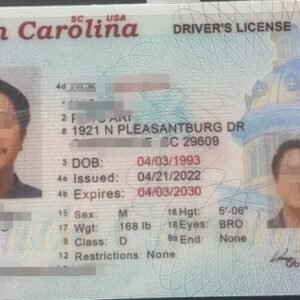

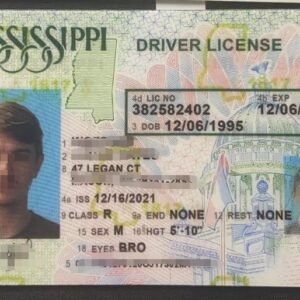

The printing processes for fake id are quite diverse and play a crucial role in enhancing their aesthetic and functional qualities. Common methods include rounded corner technology, hot stamping, UV printing, embossing, and matte film coating.

These printing techniques effectively bring out the essence of the design, ensuring that the paper’s surface is vibrant and reflective, which adds an enhanced texture and quality feel. Clear patterns not only capture attention but also add that extra touch of sophistication. Moreover, these processes serve to protect the cards from issues like yellowing, fading, and physical damage over time.

Rounded corner business card printing is a popular choice for those seeking visual appeal. Instead of the traditional right-angled edges, rounded corners provide a softer, more approachable look. Although standard business cards are normally cut with sharp edges, opting for rounded corners is a stylish alternative that can be achieved through specialized cutting machines. It’s important to note that while these rounded corners may have minor burrs, they are primarily intended for aesthetic enhancement rather than functional use.

UV printing, which stands for ultraviolet light printing, is a process where the ink is cured and dried as it is exposed to UV light. This method is especially favored in screen printing and has migrated to offset printing techniques as well. UV printing not only provides a unique finish but also enhances the durability of the printed material.

Matte film coating is another effective method, where a thin layer of plastic film is applied to the surface of the business card. This involves using adhesives that bond the film to the card through heat and pressure, resulting in a sleek, non-reflective surface that conveys elegance and professionalism. It is a preferred choice for high-end printed items that aim to leave a lasting impression.

Embossing, also known as stamping, is a technique that creates a raised pattern on the printed material by applying pressure. This method uses specially prepared metal plates to achieve intricate designs and textures. There are two varieties of embossed patterns: the more cost-efficient standard etched plates and the premium laser-engraved versions, allowing for a range of options based on budget and desired detail.

Lastly, hot stamping is a fascinating process where a design is transferred onto the card using heat and pressure, infusing metallic foil for dazzling gold or silver effects. This method, also known as heat transfer printing, enhances visual appeal and luxury, making cards stand out further in a professional setting.

These various printing technologies not only improve the aesthetics of business cards but also ensure their durability and effectiveness in networking scenarios, making them vital tools in the business world.

2. Bending tests:

Certain cards undergo bending tests to assess their durability and resistance to external conditions. Factors such as humidity fluctuations, temperature variations, poor storage practices, or improper handling techniques can all contribute to bending. These tests help determine how well the cards can maintain their shape and integrity under stressful circumstances, ensuring they are reliable for regular use. By simulating real-world conditions, manufacturers can identify potential weaknesses and improve the design and materials used in the cards, ultimately leading to a higher quality product.

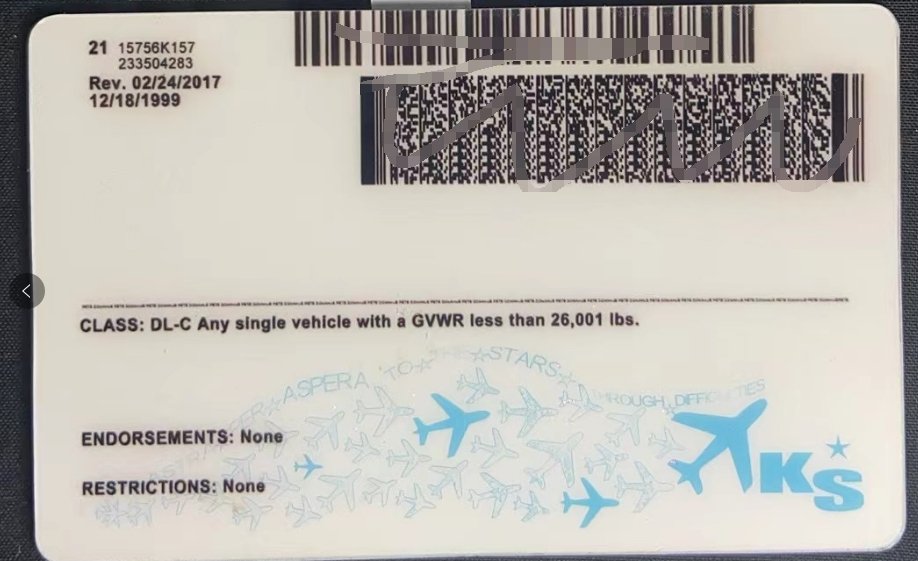

3.UV test:

The fake id cards undergo UV testing primarily to enhance their security features and combat counterfeiting. This procedure entails exposing the card to ultraviolet light, which reveals hidden patterns, markings, or elements that remain invisible under standard lighting conditions. Such UV-sensitive features act as an extra layer of verification and help authenticate the card, significantly minimizing the risk of fraud. By implementing UV testing, manufacturers can create more secure cards that provide peace of mind to both users and issuers, ensuring their integrity in various applications.

4. Printing Technology:

Our fake id cards encompass a variety of methods, each offering unique advantages. Among these, thermotransfer printing is a popular choice, where color is applied onto the card surface utilizing heat to transfer inks from a ribbon to the substrate, ensuring vibrant and durable results. Another widely used technique is dye sublimation printing, which involves a fascinating process where dyes are converted into gas and then permeate the card material under high temperatures, resulting in a seamless and high-resolution image. This method is particularly favored for producing striking colors and intricate designs that are embedded into the card, making them more resistant to wear and fading. Other techniques may include offset printing, digital printing, and UV printing, each serving distinct purposes based on the desired outcome and production scale. These diverse methods contribute to the overall quality, appearance, and functionality of printed cards, making them suitable for a range of applications.

Use materials:

Cardstock and Paper – These are the primary materials, available in various weights and finishes, providing a sturdy base for any card.

Patterned Paper – This adds visual interest and can feature diverse textures and designs, allowing for creative expression.

Gradient Cardstock – Featuring a smooth transition of colors, this material can create stunning backgrounds and effects in card designs.

Glitter Cardstock – Infused with sparkle, this type of cardstock adds a touch of glamour and shine to cards, making them eye-catching.

Woodgrain Cardstock – Mimicking the look of natural wood, this cardstock gives a rustic feel to cards, ideal for themed occasions.

Vellum Paper – Known for its translucent quality, vellum can be layered over other materials, adding depth and an ethereal touch to designs.

Parchment Cardstock – This material often features a rich texture that conveys sophistication and elegance, suitable for formal invitations.

Adhesives – Essential for assembling various elements of a card, different types of adhesives ensure everything holds together securely.

Cling Stamps – These allow for versatile stamping techniques, enhancing the design possibilities on cards.

Acrylic Blocks – zsed for mounting stamps, they help achieve precise impressions, contributing to the overall quality of the card.

The Stamp Shammy – This tool effectively cleans stamps, maintaining their performance and ensuring crisp prints.

Coloring Supplies – Markers, colored pencils, and other tools enable crafters to personalize and add flair to their cards.

Stamping Ink – Various types of inks, including pigment and dye inks, are integral to achieving vibrant stamped designs.

Washi Tape – This decorative tape comes in various patterns and colors, making it a popular choice for embellishing cards easily.

Die Cutting Machines – These machines allow for precision cutting and intricate designs that add a professional touch to card making.

You must be logged in to post a review.

Related Products

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.